Archive for January 2023

Bit Weight: A Key Factor in Drill String Design and Drill Pipe Performance

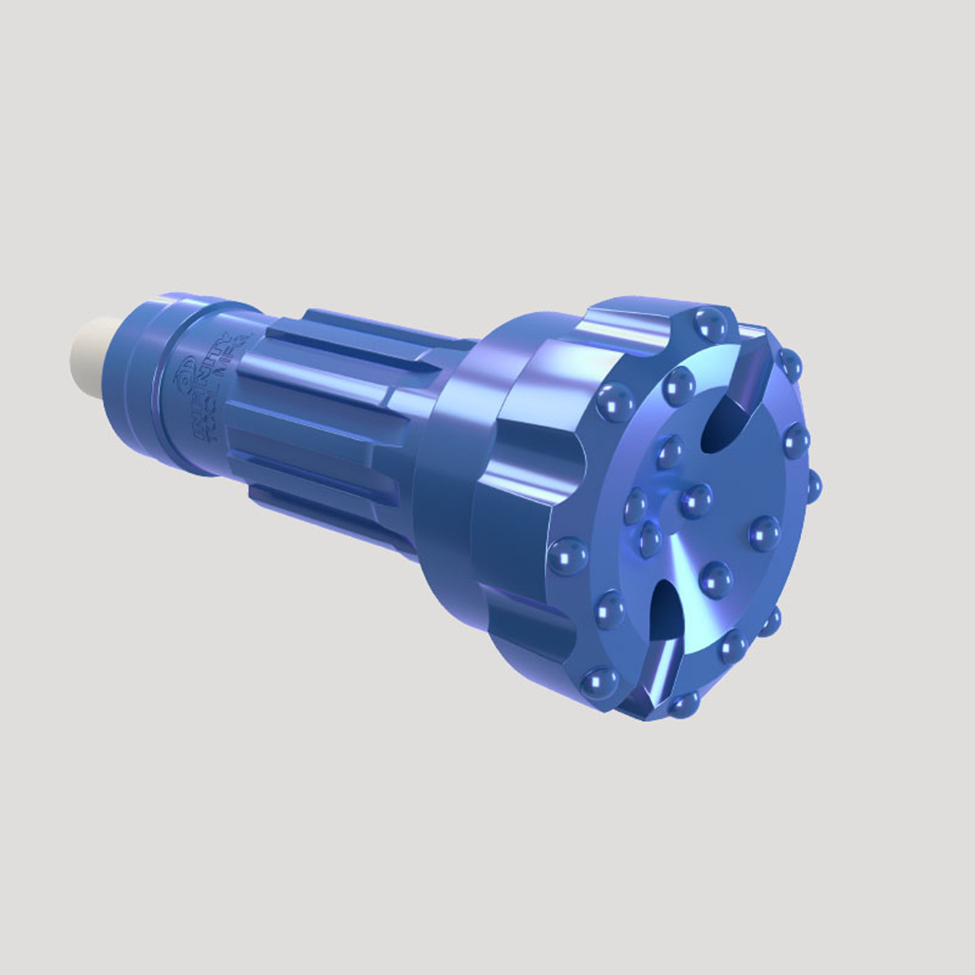

A very important factor in your drill string design & drill pipe performance is bit weight. Every bit is designed to run with a given amount of down pressure to work properly. It takes a certain amount of push. When drilling vertically, this is bit weight. Whether drilling with a tricone bit or hammer bit,…

Read MoreDrill Pipe Break In Procedures

When using new drill pipe for the first time, it is important to take care not to damage the threads and also to reduce initial wear. Below are some procedures and suggestions to avoid thread problems. Most thread problems that we have encountered occur with the first couple of uses of new drill pipe. Inspect…

Read MoreTroubleshooting Thread Problems

Thread problems are the most common problem encountered with the use of drill pipe. The purpose of this section is to help locate potential causes and correct them. It is important to note that an exact cause may not be found but the problem can be made to go away. One of the characteristics of…

Read MoreChoosing your connections. What drill pipe thread is best for you?

When you buy a rig, how much thought do you give your drill pipe and in particular to your connections? Drill pipe diameter can dictate your best hole size range to meet your needs of the type of work you do. What about your connections?Connections will dictate the internal diameter, torsional strength of your drill…

Read MoreDrill Pipe Thread Identification Chart

Click to View Thread ID Chart First of all, there are lots of threads out there that are not covered by this chart. There are Z threads, Robbins Threads, LT425 threads, Etc. With our chart, we tried to cover the API rotary shouldered connections like the API Reg, API IF, and API FH along with…

Read More